Wood Movement: Part 1 – What To Expect

WHAT You need to know about Wood Movement

If you’re considering buying a solid wood table, you need to be aware of wood movement.

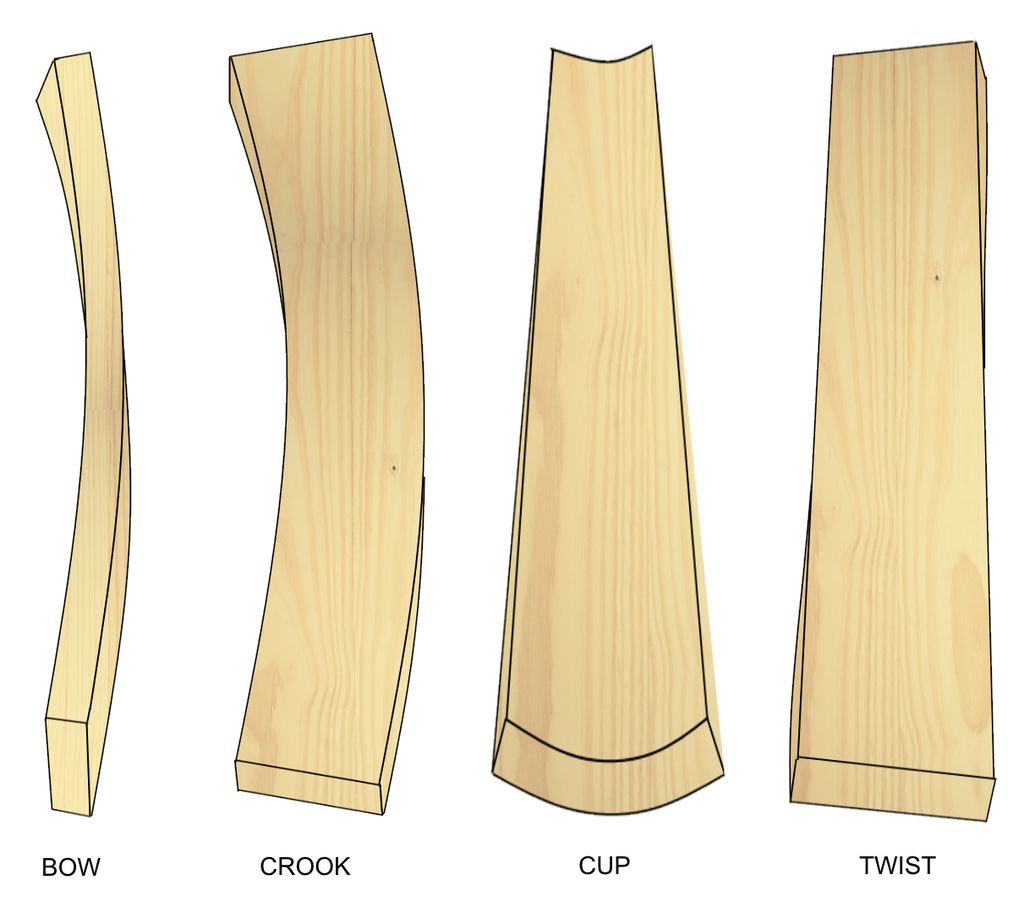

All natural timbers move, which means they can bend, twist, crack, and warp. All of these issues are classed as movement and, if not accounted for in the material choice, design, and aftercare process, can result in a table losing its lovely, even, flat, symmetrical new appearance as gaps, holes, and wobbles start to materialise, making it quite frustrating to use. Not to mention that sinking feeling of buyer’s remorse!

Wood movement happens because of the difference between the moisture content of the wood and the moisture content of the surrounding air.

As the porous wood tries to equalise its moisture content with its surrounding environment, it will let out or take on moisture, causing it to shrink and swell. And because wood is a natural material, this shrinkage and swelling does not happen perfectly evenly across the width, length and thickness of the timber, so the result can be:

- Bending and/or twisting of an individual piece of timber or across a whole table top made up of several jointed (glued) timber pieces

- Splitting along glued joints between pieces, as each piece wants to pull away from its neighbour (this often happens first at the end of the pieces where moisture loss is quickest)

- Cracking within a single piece of timber as different sections of the piece shrink away from each other, creating a small island of wood with gaps between them – the gaps are the cracks you see.

Most movement normally occurs in the first 12 months indoors, whilst the wood is acclimatising to the different conditions in your home between winter and summer.

Does it mean there’s something wrong with your wood?

Probably not. Even the process of kiln drying – which prepares timber for indoor use – can not mimic the many months of warm, dry air in a modern, centrally heated home. In fact, the kiln-drying process itself, even when digitally controlled extremely carefully over a very long period, will cause some cracking, bending and twisting.

After all, we’re trying to take something – a tree – that has lived outside its entire life (maybe 80+ years for an oak tree) and very quickly force it to adapt to a completely alien manmade indoor environment. Of course there will be consequences!

Can it be stopped?

In short – No. But there are 3 approaches you can take:

1 – Minimise the Effects of Movement.

With a basic understanding of how movement works and the different timber choices you have, you can be a lot smarter about choosing a table and creating a home environment to minimise the effects of wood movement. I’ve written this article to arm you with the knowledge to maximise the long-lasting beauty, strength and value of your oak table.

2 – Correct Any Movement Once it has Stopped.

Because the majority of any major movement will take place in the first 12 months, once the wood has settled any cracks can be filled and any uneven or un-straight (if that’s a word) edges can be straightened. The aftercare service we provide with every table guarantees you the peace of mind of knowing you’ll have an acclimatised table that looks like new, with minimal risk of any further visible or structural changes.

But just because a table is made from solid wood does not mean it can be refurbished – many can not and I call these “disposable tables”. And for those that can be restored, the cost can be huge. I’ve written this article to explain the difference between a table you will need to replace, versus a table that will last you indefinitely.

3 – Consider Alternatives

Knowing that wood movement is an almost unavoidable reality of owning a solid wood table, you can choose a maker who guarantees your peace of mind by dealing with any issues you might encounter, or you might want to at least consider a different material for your table. In an article coming soon I explain the alternatives to solid wood and their pros and cons.